The experience of working in the field of invention, new product innovation and machine development has given us insight into the new possibilities and changes coming from the sky. For Inventors it is blue skies and the playing field is equal. To start, look out into the air and look up. You know that billions of bits of information are streaming by your head and you can not see or sense it. The towers and satellites above and reactive software are working together to connect the dots across the globe in milliseconds. The point is if you can’t see it does not mean, it is not there. The key to the modern design world is to know what you don’t know. While we are going about our daily lives the past ten years, the internet is on generation 4.0 and the Internet of Things, whole process from top to bottom is linked to an increasingly smarter, hardware and software artificially intelligent universe. The industry operates in clouds and big data using real time smart and predictive analysis to run our lives. The design programs are now designing themselves, and designers know a lot about it.

The result is Industrial Designers, Engineers, Manufacturers, and the Marketing Advertisers are teaming up with the big media giants and using the big data they have access to, to create portals to the small individual products and services that we desire. Designers know because we log on, look and communicate those needs, volunterily or not by the internet and phone. The voices are transcribed, words are generated and captured into algorithms with prioritized statistical aanalysis and graphic output digital data. The Designers are directed and financed to interpret and apply the big data results to create and generate the little 3D virtual world of product assemblies, made from mass produced parts. The product development process is driven by the Industrial Designers to create design, build, test and sell all in the universally friendly, digital format. Knowing how to utilize and operate in the digital format of CAD Computer-Aided-Design and predicitve analysis software and applications is the key to success. Inventors must know what they are up against and how to use this rapidly changing technology of big data to their advantage.

In Design and Supply, big data involves everything from tracking and managing raw materials acquisition to the shop floor to land fill cycle. Big business is owning and controlling the raw materials, the data and the supply chain. The whole process, hardware and software is now so sophisticated that no one person can create the more intelligent product or service they produce. It takes a very large team of very smart people to deliver the big data management system with the package to the store or your door. The customer purchases based on need and desires and the suppliers react, making the requests for the new – cheaper manufacturing driven designs to the more efficient distribution channel to the customer. Color rendering to store shelf, the big boys can now do in weeks. The defining success is how too and how fast can they react to get the needed media exposure to the largest global markets.

Back to square one. What you need to consider is what you don’t know can lead your business down very quickly. Know that if you consult with a smart team who operates in the big data world, you have a much greater chance of using that technology to your advantage and market penetration. Know what you don’t know and think prototypes to market is not the typical 18 month process any more.

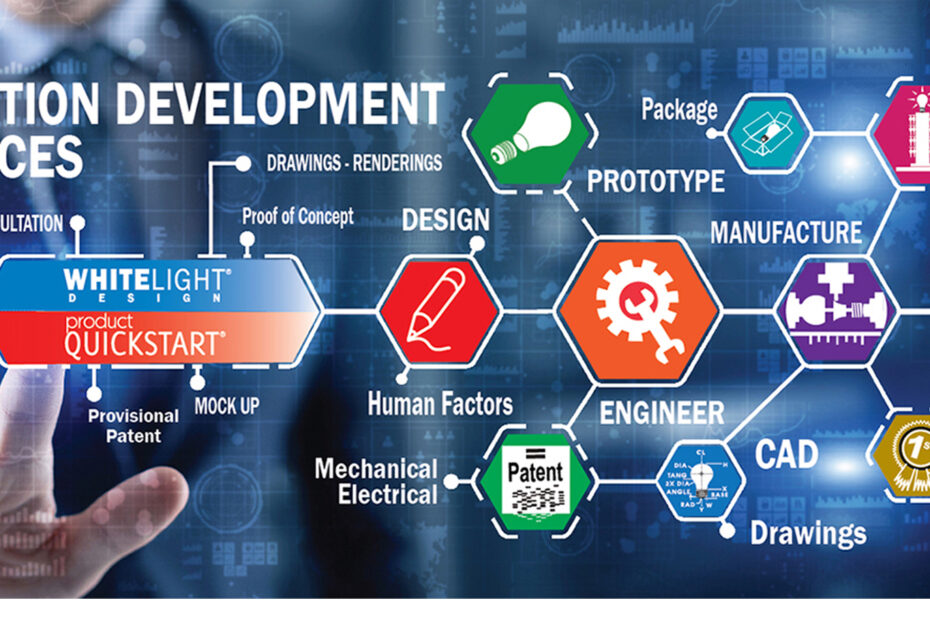

Working with Whitelight Design, you can typically use Industrial Design (design for mass production) and 3D CAD modeling to prototype a design in 6-10 weeks. From there in 3-4 weeks you can produce RTV Cast Urethane prototypes that can be put in a box with a laser print label and ship anywhere in the world, in two days. The rapid prototyping process is being used to test market products prior to the typically large time investment of hard tooling, forming sheet metal or injection molding plastic. The whole process is managed in the virtual world and the key data is the 3D CAD file of your product. That data gives you the ability to work with the design house or the manufacturer to produce units needed to fulfill orders. The “in the know” are using the big data and rapid prototyping processes including (additive manufacturing) Stereolithography(SLA) and Polyjet for plastics and Fusion Deposit Modeling (FDM) and Laser Metal Sinthering (LMS) of metals to make prototypes and products appear in days.

Now you know a little more about the blue skies, what you may know and what you do. Big data and rapid prototyping are now leveling the field of the known areas of equal opportunity. Also see our Strategic Development Process Any questions, we are here to help. Contact Us…Above!