CAD / COMPUTER-AIDED DESIGN

Computer-Aided Design Design-Engineering-Manufacturing (CAD-CAE-CAM) are the main tools within industrial design, product development and production manufacturing. The benefit is that computer models become a quality control standard and speed to market. A primary benefit is a virtual model of your design can be changed or updated in mid-process. Or used to help predict failure or performance through Computer-Aided Engineering (CAE), which are add-on mechanical simulation programs; such as injection mold flow, force, stress, and deflection testing. The end goal is the CAD data is translated to the Computer-Aided Manufacturing (CAM), prototyper and manufacturer for tooling development, to mass manufacture the product. The main power of CAD is the ability to achieve much more complex geometries or styling shapes while maintaining manufacturing tolerances and quality control. CAD files can also be used to create photo-realistic images and animations of your product or package.

Application of CAD

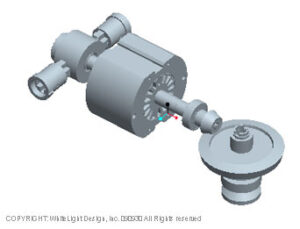

Application of 3D CAD modeling can be very efficient in constructing complex electronic and mechanical assemblies such as an automobile, to create multi-component 3D part mechanical assemblies, for fit tolerance and geometry fit checks. The CAD model combined with the utilization of CAE – Finite Element Analysis (FEA) for structural and behavioral analysis, leading to Computer-Aided Machining (CAM) for machine, mold, die, tool or part creation, for and Rapid Prototyping (RP) – CNC, SLA, SLS, RTV, is a complete computer-controlled product development system.

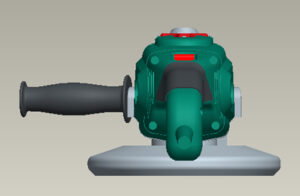

CAD = 3D Visualization

The CAD development process helps to visualize and expedite the product development process allowing Industrial Designers and Engineers to define the critical appearance and mechanical assembly of a product supporting the process of defining feasible molding geometries, materials and manufacturing process selection. The CAD-CAM data is also used for manufacturing part and assembly automation, defining machine requirements, tool paths and cutting rate speeds, creating production tooling – injection molding cavities and cores, manufacturing robotics assembly, quality controls, part inspections, etc. In the right hands, CAD is your most powerful tool to design, test, manufacturer, assemble and package a product. With use of professional Industrial Designers and Engineer who utilize CAD-CAE-CAM programs an entrepreneur can avoid making very expensive mistakes.

Working with WhiteLight Design

Working with WhiteLight Design and our CAD system greatly increases your chances of getting it right the first time and avoiding costly Engineering Change Orders. If you have any questions about or CAD system, please just give us a ring!