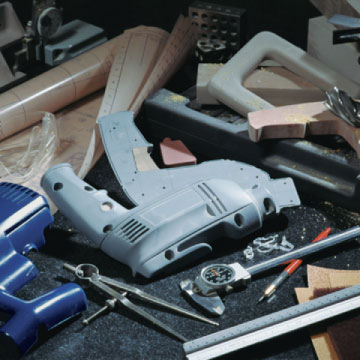

Prototypes are invaluable. The word Prototype has a very wide range of applications and costs to fabricate. For the Industrial Designer they are an essential part of invention and product development. Prototypes can range from a very rough cardboard full size mock-up to a POC – Proof of Concept functional prototype model to validate primary function and intended use to a full marketing or appearance prototype.

Many Prototypes end up in the trash bin meant only to review and study the design solution. Prototypes support documenting an idea and most important how the applied human factors are considered. The fully functional full appearance quality comes at a relatively high price. For the Designer who is the end users or consumer input the most valuable prototypes are the ones that fail or break. We often learn a lot from a quick mock up or a failed prototype in new product development. Thomas Edison failed a 1,000 times of times before achieving the mass produced commercial light bulb. “I didn’t fail 1,000 times. The light bulb was an invention with 1,000 steps.” “Great success is built on failure, frustration, even catastrophe.”

The process of generating the physical prototype often opens up unanticipated issues and new areas of thought, learning from and eliminating the bad design to create a successful product design. The most valuable contribution is the user perspective with the Human Factors sizing and product interface semantics. The semantics considers the physical proportions and interaction with the product considering safety and comfort for toddler to expert users, and the 5 sensory factors, touch, sight, hearing, taste and smell or the full User – Product Interface. The small business lesson is invest in prototypes knowing they may fail and also provide invaluable input to develop the best design solution. Make prototyping a fundamental part of your product machine or device development process.

Once your prototype works like intended then you can be much more confident in proceeding to full 3D CAD-CAM manufacturing – tooling and and final prototype development. Marketing – Sales prototypes for trade shows is a solid investment, but the prototyping that leads up to that final appearance quality prototype can give the confidence that says, now invest and go make 3,000 units that we can sell.

Rapid prototypes is the additive model making process of using the 3D CAD files or part files converted to the .stl format and a tracking laser light to produce the 3D part by layers in a curable liquid or molten polymers. Stereolithography(SLA) or Fusion Deposit Modeling (FDM) are the 2 relatively low cost processes available. Appearance models can be made by finishing and painting the SLA models which are usually non functional used to display the product only, to confirm the response and potential for market acceptance. Most investors are sold on the POC or appearance prototype to invest.

To get simulated injection molded functional appearance models the Rapid Thermal Vulcanization or RTV process is used. The RTV process uses the 3D CAD part files to produce cast gravity or vacuum feed urethane rubber molds using the printed SLA matter pattern models to then cast produce urethane parts which simulate production quality plastics, textures and colors. You may get 10 – 20 cast parts out of each mold. Functional parts can also be produced by Computer Numeric Controlled (CNC) lathe or mill (See ASK WhiteLight Prototype Shop) for producing wood, metal or plastic parts in the subtractive removing material from a block process.

The CNC and RTV processes to produce functional appearance prototypes are used when you want 10- 20 units to to conduct focus group and test marketing. Without investing in hard – injection mold tooling.

Today rapid prototypes produced by SLA, FDM and RTV have advanced in materials toughness and are now commonly used a low volume products including the satellite and aerospace industry. We have delivered many CNC stainless steel or aluminum parts for Medical Doctors and Surgeons.

WhiteLight Design is focused on inventor-entrepreneurs and small to mid-sized companies that embrace the entrepreneurial spirit. Learn the prototypes lessons before they become very expensive to fix. If you need help with product industrial design, product design engineering, manufacturing development and the most valuable prototypes, you are now plugged into the Enlightened Solution!

WhiteLight Design www.WhiteLightDesign.com

inquiry@whitelightdesign.com TEL: 770 277-7097