Are you looking for top-notch 3D CAD drawing services in Atlanta or the surrounding area? WhiteLight Design is ready to help. Our Atlanta state-of-the-art 3D CAD drawing services, product design engineering, and manufacturing assistance, are second to none.

CAD Computer-Aided Design

CAD – CAE – CAM is shorthand for CAD or Computer-Aided Design, Computer-Aided Engineering, Computer-Aided Manufacturing and speed to market. We create a virtual 3D CAD model of your product with all the parts and assembly or CAD files that are translated to additive and subtractive prototype or manufacturing build programs combined with 3D printing rapid prototype technology. The CAD–CAE-CAM system allows WD and our full prototype shop to transform your idea from the sketching page to the virtual world to the 1st prototype to the manufacturing production assembly line in weeks. These 3D CAD/CAM and rapid prototyping services are key to getting your product from vision to reality. We can typically deliver in several weeks. By utilizing our 3D CAD drawing services, it improves communication between you and your team to increase productivity. 3D CAD renderings allow you to easily visualize your proposed ideas and plan how to execute them, saving you time.

We have invested in “state of the art” hardware (Dell) with established and proven 3D virtual modeling, surface and parametric CAD software (CREO, SolidWorks, Rhino, Adobe).

CAE Computer-Aided Engineering

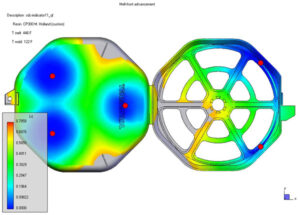

CAE, Computer-Aided Engineering is the use of the generated CAD modeling data for supporting manufactured part development or assembly and predictive analysis or finite element analysis tasks such as force loading and stress cycle analysis, accelerated environmental simulation, thermal analysis for part-tooling/mold design. CAE is an add-on mechanical simulation programs; such as injection mold flow, force, stress, and deflection testing. CAE is about predicting how a part or product will react in the real world. It is a simulation of geometry and applied forces or heat to predict how the part will perform in use. For example how long will a door hinge last and how does it fail in extreme conditions . Other uses for CAE include manufacturing and assembly optimization, planning, diagnosis and servicing and repair.

CAM Computer-Aided Manufacturing

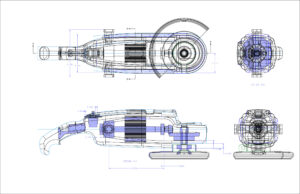

CAM, Computer-Aided Manufacturing and CNC Computer-Numerical Controlled Machining uses the CAD and CAE data for development of tooling, machining, manufacturing or 3D Rapid Prototyping. Designing and Engineering and CAD modeling for cost-effective Manufacturing is the driving force behind CAD, CAE, and CAM. The prototype shop or manufacturer uses the CAD data to convert to machine programs for additive and subtractive prototype or manufacturing, (ex. CNC cutting aluminum blocks), injection molding, or thermoforming plastics machine programs.

WhiteLight Design’s CAD team brings over 20 years of team experience, working to solve simple to very complex 3D CAD-CAE-CAM mechanical problems and bring your idea to reality. We have an integrated system of industrial design, engineering, and CAD-CAE-CAM manufacturing (Strategic Development Process) with a successful track record of developing products and devices that work as intended and make it to the store shelves. We produce accurate, detailed 3D CAD renderings, achieving our clients’ desired results every time. Additionally, our engineers use the latest process and graphic accelerators for successful product development.

3D CAD Color Renderings

Don’t wait any longer. If you need 3D CAD drawing or rendering services, then WhiteLight Design is your all-in-one solution. To discuss how our Industrial Designers and Design Engineers will use our CAD-CAM systems and Capabilities to save you time and money, please call for an initial review of your needs.