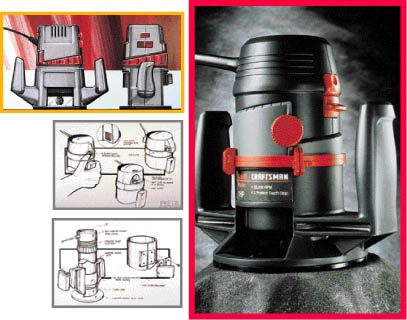

GOLD AWARD Industrial Design Excellence Award 1991

Annual product design competition sponsored by The Industrial Designers Society of America and Business Week Magazine

IDA CLIENT: Ryobi Motor Products, SC

Product Development – Ramp Lock Router -power tool – prototype – team work performed by Willis Whiteside while working with Industrial Design Associates, Inc. Principle Industrial Designers: Mr. Jim Watson & Mr. Alex Chunn, Mr. Bill Austin, Mr. Sam Crosby, Mr. Doug Alsulp, Mr. Bill Saunders, Mr. Chris McClintock.

Working with the client’s engineering team this was a complete product development project that encompassed concept generation through production design. The heart of the design solution is the patented, ramped step-ring that allow the user to incrementally adjust and measure the height of the router bit. This is a prime example of an old school industrial design project completed when CAD was just getting started and only in 2D. The product design was delivered in a fully dimensioned line drawing format to the product design engineers who then turned the 2D information into the 3D injection mold tooling. The art of mold making in the day was no less a bit of modern magic. Additionally CNC machining software capability to interpret the 2D drawings to translate into the 3D injection moldable geometry. The work included development sketches, color renderings and an appearance model of the final product design. The design work was completed as part of a team at Industrial Design Associates (IDA), at the time located in Decatur, GA. The 90’s was prime time for evolving Industrial Design and CAD Design software and the corporate power tool R&D search for new ideas and improved user -product interface continues today.

DESIGN INNOVATIONS:

• Patented Incremental Ramp Lock router height adjustment mechanism

• 1 piece injection molded base housing

• 2 piece injection molded clam shell motor housing

• User friendly switch/knob orientation

Photography courtesy of Bjorn Shultz, Cave Productions

Industrial Design – new product development is about solving problems. From pencil thumbnail sketches to 3D CAD color renderings the design process is about visualizing the possible solutions or design to meet the physical requirements. Industrial design embraces semantics and keep it simple with the use of figure ground presentations, 3D CAD, product engineering and rapid prototyping. The 3D CAD – shop drawings with all the dimensions needed is the key to working from paper to fully assembled prototype. The team has invested in a rapid printed prototype shop to complement the full prototype shop. New materials and production technologies are used to meet the product materials and performance demands. Our Designers look for the highest quality possible with sincere commitment to performance and human factors friendly solutions that compliments the environment. WhiteLight Design uses industrial design and product design engineering to create efficient and elegant product design and manufacturing solutions. From plastic to metal to aluminum to titanium, metal to plastic conversion our engineers work to model up the invention from the patent. If you and company are looking for product design give the shop a ring.