Product Prototype Service

If you’re on the hunt for product prototyping and problem solving services in Atlanta or the surrounding area, then the WhiteLight Design is your solution.

The ASK WHITELIGHT Full Prototype Shop in the Norcross, Atlanta, GA has over 25 years of team experience, access to equipment, materials knowledge, and integrity to aide you in producing a tangible preview of your invention or ready for the store shelf product design. The Prototype shop is led by Mr. Scott Stewart with the team. Problem solving with invention support, rapid prototypes are our specialty. Either shark bitten or an upcoming trade show, when deadlines and Speed to Market are important, our product prototype development services will rise to the spotlight challenge.

Our offerings are second to none, and we have everything you need to make the prototyping process as easy and streamlined as possible. We offer full size – Mock Up models , POC- Proof-of-Concept, and Proof-of-Design with fully functional prototypes or show quality exhibit appearance models.

CLICK HERE to see the Product Quickstart Printed Rapid Prototype shop.

We utilize rapid prototyping technologies, including SLA-SLS-FDM and RTV– Cast Urethane and full rapid CNC machining. Wood, metal, plastic, carbon fiber or titanium if requested deliver prototypes of complete products, product components, or machined parts in 5-15 days, thereby saving you time and money. Our modelmaking and prototype services include the following:

Rapid Prototype – Printed Models

Proof of Concept – Mock Up – Functional Models

Marketing / Appearance / Display Models

Rapid Metal – CNC Machined Models

Rapid Molding & RTV Cast Urethane Models

You will soon appreciate the clean and organized ASK WhiteLight Design – Prototyping Shop where on time delivery is common practice. We offer friendly and professional protote model support proudly servicing the Lawrenceville, Suwanee, Norcross, Buford, Roswell, Alpharetta, Smyrna, Marietta, Fulton, Decatur, Conyers and greater Atlanta, GA areas.

We typically have to create the design and 3D CAD files or drawings before we can go to the shop or RFQ quote the parts or full assembly model. For questions or to schedule an initial consultation or request a Model Making or Prototype quotation please call us. We will need to review your design – drawings, prototype or CAD information to provide a quotation. Remember—for product development prototyping services that won’t let you down, choose WhiteLight Design. We’re looking forward to working with you!

Prototype Development Confidence

Prototype or prototyping development – new product development is about solving problems. Prototyping is about proving out the design leading to confidence of proceeding to mass production. Prototyping is also limited to the additive or bock materials available not always able to simulate the actual materials or mechanical performance of the injection molded or diecast part. From crude cardboard mockup to fully functional show quality prototypes. ALPHA or BETA prototypes are used to prelaunch or test market before mass production and tooling investment.

Prototypes Developed in Stages.

Prototypes are developed in stages or different levels of complexity. Mechanical or electrical powered prototypes are also developed in stages. Electronics – AC 100V or battery powered Hardware and Software – Graphic User Interface program development is also developed in stages. Mechanical Prototype development stages:

- Proof of Concept – Working – non appearance – breadboard PCB (Printed Circuit Board) display – no enclosures

- Working – non appearance – breadboard PCB (Printed Circuit Board) display – with mock up plastic enclosure, limited ID.

- Working – full ID appearance – PCB (Printed Circuit Board) display – 1 unit plastic printed prototype enclosure

- Working – Alpha full ID appearance quality 1 – 20 units PCB (Printed Circuit Board) display – RTV Cast Urethane (rubber tools), urethane prototypes. Simulate injection molded part with color and graphics.

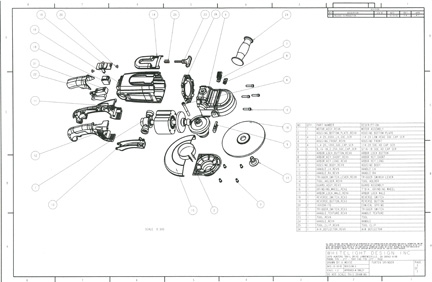

3D printed plastic to CAD – CAM milling

From pencil sketches to 3D plastic printed to 3D CAD – CAM milling stations the proto process is about materializing the solution or mechanical design to meet the physical requirements. Industrial design embraces semantics and keep it simple with the use of quick 3D printed models. The 3D CAD can also produce shop drawings with all the dimensions needed is the key to working from paper to fully assembled prototype. The team has invested in a rapid printed prototype shop to complement the full prototype machine shop. New materials and production technologies are used to meet the product materials and performance demands. Our Designers look for the highest quality prototype process possible with sincere commitment to solutions that exceed expectations. WhiteLight Design always aims to create efficient and elegant product design and manufacturing – prototype solutions. From plastic to metal to aluminum to titanium, metal to plastic conversion our engineers work to model up the invention from the patent. If you and company are looking for prototype design shop give the shop a ring.

ASK WhiteLight Prototype Shop – General Questions: Willis Whiteside willis@whitelightdesign.com