ASK WHITELIGHT PROTOTYPE SHOP

ASK WhiteLight Prototype Shop

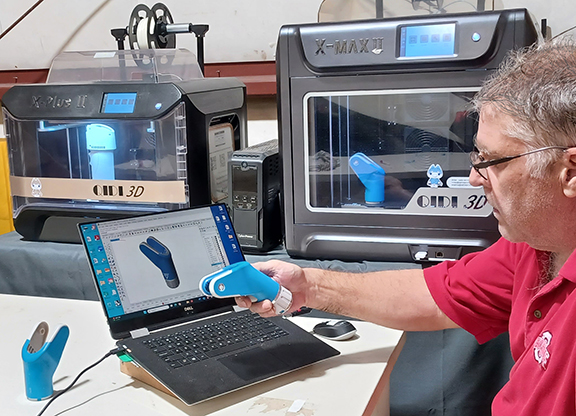

The ASK WhiteLight Design Prototype Shop has been the birthplace of many ventures and POC Proof of Concept models, known for our creative thinking, extensive experience lite up with quality and friendly service, in Norcross, Georgia. The heart is the team’s experience has been working together in the model making shop to share and problem solve together, as the keys to our success.

Problem solvers

Led by Scott Stewart, the ASK Prototype shop key is the history of a automotive machine prototype shop with medical product capabilities combined with a working 3D CAD – CAM – CNC machining- tooling system, tuned into a small prototyping manufacturing cell. The model making shop capabilities include traditional wood, metal and plastic, working equipment including most materials; aluminum, steel, carbon fiber and titanium combined with some state of the art CAD-CAM hardware and software, all used and proven. (PROE /CREO(R) – SolidWorks(R) – MasterCam(R))

The real heart of the business is our close Team with the supporting Engineers, Technicians, Craftsmen, Modelmakers and Rapid Prototypers and that extensive experience problem solving and making dreams come true.

We often deliver prototypes in days thereby saving you time and money in this very competitive world economy. You now have the team, skills, access to equipment, materials knowledge and synergy on your screen or front pocket. For a complete review of our capabilities or a personal shop tour related to your project, please call us and ASK WHITELIGHT at (770) 277-7097. By Appointment only.

BASIC EQUIPMENT LIST

Problem Solvers

The ASK WhiteLight Prototype machine shop led by Scott Stewart has a history of a automotive machine prototype shop with medical product capabilities combined with a working 3D CAD – CAM – CNC machining- tooling system, tuned into a small prototyping manufacturing cell. The model making shop capabilities include traditional wood, metal and plastic, working equipment including most materials; aluminum, steel, carbon fiber and titanium combined with some state of the art CAD-CAM hardware and software, all used and proven. (PROE /CREO(R) – SolidWorks(R) – MasterCam(R))

The real heart of the business is our close Team with the supporting Engineers, Technicians, Craftsmen, Modelmakers and Rapid Prototypers and that extensive experience problem solving and making dreams come true.

We often deliver prototypes in days thereby saving you time and money in this very competitive world economy. You now have the team, skills, access to equipment, materials knowledge and synergy on your screen or front pocket. For a complete review of our capabilities or a personal shop tour related to your project, please call us and ASK WHITELIGHT at (770) 277-7097. By Appointment only.

BASIC EQUIPMENT LIST

- 1 Okuma Howa 511 CNC vertical Milling Machine (4 Axis’s capability) – 40″x 20″x 20″

- 25 Stations Tool Changer Fully Tooled

- 4 – Bridgeport Milling Machine – 2 Proto Trak+ Electronic Control, 2 D.R.O. equipped

- 5 – Lathes – 17” x 40” – 17” x 60” With Travadials, 12” x 24” – 8” x 24” Turret

- Hardinge Chucker

- Die Filler

- 6 Drill Presses – High Speed Small Hole Drill Press

- Grob 18” Band Saw

- Powermatic 14” 2 Speed Band Saw

- Marathon Cold Cut Off Saw 4”

- Kalamazoo Horizontal Saw 12” x 18”

- Harig – 6 x 12 Surface Grinder

- Pedestal Disc Grinders

- Lincoln Pro-Cut 60 Plasma Cutter

- Miller 250 Amp Heliarc Welder

- Miller 350 Amp Syncroway Welder

- 36” Diacro Roller (2” Rolls) & 49” Roller (3” Dia. Rolls)

- 52” Wysong Shear 16 Gauge (Hydraulic)

- 48” Finger Brake 16 Gauge Capacity

- 48” Finger Brake 10 Gauge Capacity

- 36” Magna Bend 16 Gauge Capacity

- Shrinker 17 Gauge / Stretcher -16 Gauge

- Corner Notcher -16 Gauge

- Nibbler -16 Gauge

- 12” Diacro – Modeling Shear -16 Gauge

- Air Former

- Niagra Beading Machine

- Pexto Beading Machine

- Weiderman Turret Punch (Manual)

- 24 x 36 Bead Blaster

- Anodizing, Painting and Finishing (available upon request)